一、Technology and application of the large flow degassing membrane

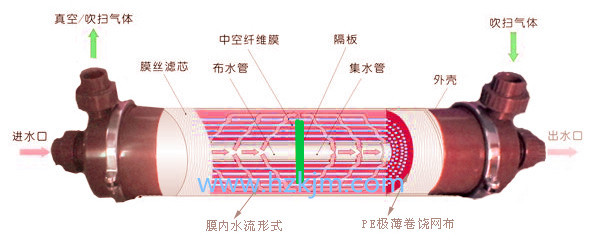

(一).Structure diagram(High pressure resistant & External pressure type) Figure 1

(二).Characteristics of the large flow degassing membrane:

1.By the technique of continuous control stretching,to precise control the porosity and pore size of the membrane;

2. Through the special hydrophobic treatment, according to the number of 2000 membrane silks as a bundle, the membrane hole into the pure water (pressure:0.30Mpa) are pre-detecting of membrane silks, pick out the broken hole membrane silks, to ensure the finished membrane silks permanent "breathable impervious";

3. The membrane silk after the special pre-detecting,using the special weaving process,making the membrane silks in the form of winding shape in the internal component,filling more uniform,gas / water contact surface effectively,and the degassing efficiency is greatly improved;

4. Packaged of membrane element, set the middle plate,making the gas/water on both sides of the contact more fully, the effect is better;

5. Packaged of membrane element, using the PE mesh grille to wrap membrane silk,to ensure that wont thrust membrane silks under high hydraulic pressure,and have a certain effect on the blocking flow,making contact with water and the gas phase membrane silk more uniform;

6.Liquid inlet temperature:about 25℃,pressure≤0.6Mpa;temperature:60℃,pressure≤0.2Mpa。

二. Internal pressure type degassing membrane

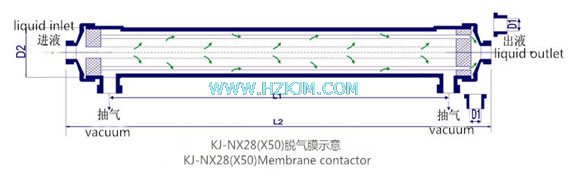

(一)Structure diagram

(二)Characteristics of the internal pressure type degassing membrane:

|

1.By the technique of continuous control stretching,to precise control the porosity and pore size of the membrane; 2. Through the special hydrophobic treatment, according to the number of 2000 membrane silks as a bundle, the membrane hole into the pure water (pressure:0.30Mpa) are pre-detecting of membrane silks, pick out the broken hole membrane silks, to ensure the finished membrane silks permanent "breathable impervious"; 3.Liquid inlet temperature:about 25℃,pressure≤0.2Mpa(The differential pressure of liquid inlet and vacuum is smaller than 0.3Mpa);temperature:60℃,pressure<0.1Mpa; |

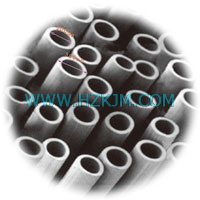

The membrane wall hole |

The size of hollow fiber membrane |

The picture of the amplification degassing membrane silk |

The membrane silk after weaving |

Degassing membrane specific parameters

(一)Parameters of large flow degassing membrane

|

Model |

Inner/outer diameter |

Design flux(T/H) |

Connector type |

Size(mm) |

|||

|

L1 |

L2 |

D1 |

D2 |

||||

|

KJ-6X28WB |

200/300µm |

1.0~5.5 |

Flange |

768 |

1012 |

40 |

160 |

|

KJ-SH6X40WB |

1.0~7.5 |

UPVC |

1035 |

1260 |

40 |

160 |

|

|

KJ-SH8X40WB |

4.0~12.0 |

UPVC |

1210 |

1257 |

50 |

200 |

|

|

KJ-SH10X40WB |

4.0~20.0 |

DN50 COUPLING |

1070 |

1210 |

60 |

250 |

|

|

Porosity |

38~40%;45~55% |

||||||

|

(Membrane/ adhesive material) |

Special processing of pp/polyurethane |

||||||

|

(Max pressure/ Temperature) |

25℃,0.60Mpa;60℃, 0.20Mpa |

||||||

|

PH range |

1~14 |

||||||

(二).Parameters of internal pressure type degass ing membrane

|

Model |

Inner/outer diameter |

Design flux(T/H) |

Pressure/ temperature |

Size(mm) |

|||

|

L1 |

L2 |

D1 |

D2 |

||||

|

KJ-H4X28MB |

350~370/450~470µm |

0.3~0.9 |

25℃,0.20Mpa 60℃, 0.10Mpa |

920 |

1073 |

32 |

90 |

|

KJ-SH4.8X28MB |

0.6~1.6 |

1066 |

1290 |

32 |

119 |

||

|

KJ-5X28MB |

0.6~2.0 |

830 |

1054 |

32 |

140 |

||

|

KJ-H6X28MB |

1.0~3.3 |

1050 |

1420 |

40 |

160 |

||

|

KJ-SH7X28MB |

1.2~4.3 |

1035 |

1405 |

50 |

180 |

||

“The application of CO2 and O2 removal by membrane method”please click into

KJ-6X28(40)large flow degassing membrane |

KJ-SH10x40WB large flow degassing membrane |

KJ-SH7X28MB Internal pressure type degassing membrane |

Small type internal pressure type stainless steel degassing membrane |

Degassing membrane

Degassing membrane

33011002012349

33011002012349