The technology and cases of removal of CO2, O2 in liquid by membrane method

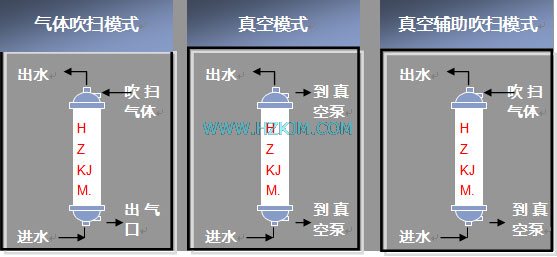

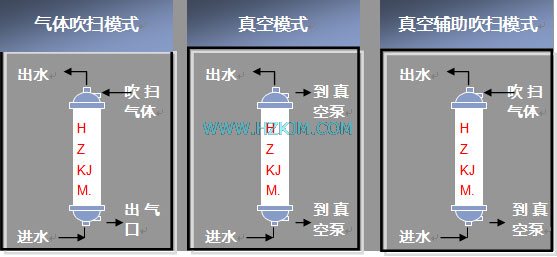

Three different operation modes of membrane Contactors

Degassing membrane (X50/X40 close gas membrane silk) technology is a new type of gas / liquid membrane separation process,By vacuum pumping, vacuum pumping+N2 method,the O2 removal rate is greater than 95%/99% in water,by method of blowing gas can make the CO2 removal rate is more than 95% in water,The users can also use series method to further improve the degassing effect.

“The design guides of CO2 and O2 removal by membrane method”please click into

Scope of application

-Remove the O2 in the liquid(< 1 ppb)

-Remove the CO2 in the liquid(< 1 ppb)

-Remove the N2 in the liquid

-Control humidity of gas

-Remove the micro-bubble in the liquid(Such as: photoresist, color ink, emulsion)

-The addition of hydrogen in liquid to control the dissolved hydrogen

-The addition of nitrogen in liquid to control the dissolved nitrogen

-The addition of carbon dioxide in liquid

Widely used in boiler feed water, food and beverage, semiconductor ultrapure water industry.

Degassing membrane compare with the traditional degassing tower

1. The traditional technology of removal of oxygen and carbon dioxide,bulky equipment, transportation and installation are not convenient , and the removal efficiency is limited, high operation cost.

2.Using the technology of KJ-Membrane degassing membrane, can be easily removed O2 to below 5ppb , the CO2 removal to below 1ppm, and the KJ-Membrane degassing membrane modular installation, the volume is reduced, the operation cost is cheap, the service life is over five years (water area), the automatic control, convenient use and maintenance.

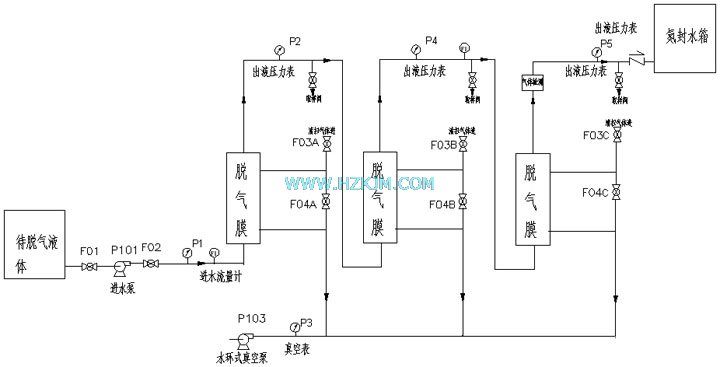

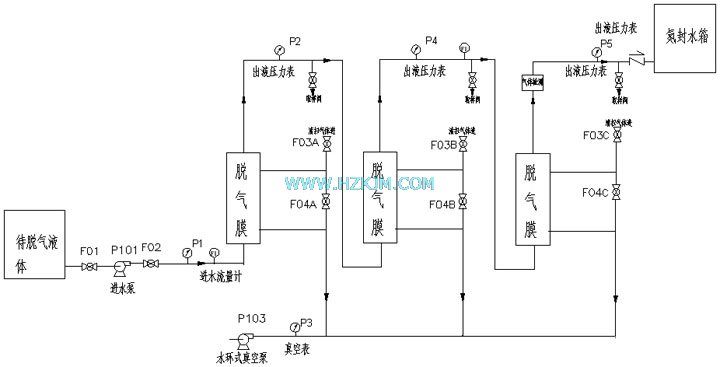

The introduce of membrane contactor Leve 3 series process:

Membrane contactor Leve 3 series diagram

Use of degassing membrane:

(1)CO2 removal in liquid

The water for reverse osmosis (RO) and electric desalting (EDI) or continuous electric desalting (CDI) system must reduce the content of carbon dioxide (CO2) in water.High conductivity of electric desalting (EDI) or continuous electrical desalting (CDI) will decrease the resistivity values of yielding water.Dissolved CO2 in water is the main reason to cause the high conductivity .Kaijie Membrane Contactor degassing membrane provides a clean, free of maintenance and without any chemical added to adjust PH value,the method of removing CO2 in water ,the removal rate can reach 99.9%.If removing CO2, before EDI or CDI, then, will allow EDI or CDI produce higher quality of water,so that the water resistivity of original one level RO+EDI increased from 1 megabyte to 18 megabytes.After removing the dissolved CO2 in water,EDI/CDI on silicon and boron removal rate also increase,so that one level of RO + degassing membrane completely replace the previous two level series RO water,as the electric desalting (EDI) water become possible.

(2)O2 removal in liquid

Kaijie Membrane Contactor degassing membrane is widely used to remove oxygen in water and other liquid .Oxygen have a negative impact for many processes, it can corrode and oxidate material.In the field of electric power and other industrial, if not for degassing, pipe, boiler and the equipment will be easy to be corroded.Kaijie Membrane Contactor provides a method of deoxidization in water that without chemicals addition and large degassing tower,and it’s easy operation and modular.Also provides only need one step to achieve that removal both O2 and CO2, and the benefits of N2 control.Widely used in the field of semiconductor, in the field of semiconductor and film tablet industry, the high oxygen content can lead to low rate.In the field of microelectronics, Kaijie Membrane Contactor can meet index of dissolved oxygen< 1 PPB and provides the guarantee of performance.Fully provides a perfect solution to replace the degassing tower.

(3)Nitridation

Putting the nitrogen into the liquid, can improve some process.For example, if oxygen is removed in the liquid, and then some of the nitrogen is added to the water, and can improve the ultrasonic cleaning.KJ-membrance Membrane Contactor provides a perfect solution, because it is easy to remove oxygen ,and it can complete a controlled nitriding process.

In different engineerings of food & beverage industry put nitrogen into the liquid .If you want to have more bubbles or a thick layer of foam on top of the beer,nitridation is the best step .Membrane Contactor provides a simple and embedding step, can make the diffusion of nitrogen in a controlled process to add it, and produce a more stable products.

(4)Carbonation

Membrane Contactor provides a kind of simple and effective method of filling the carbon dioxide into the drink and liquid.Carbon dioxide gas is added to the beverage,can give the beverage foaming and stimulating.The addition of carbon dioxide can prevent deterioration, and reduce the bacterium of liquid.

Far better than spraying a large number of CO2 bubble to the liquid,membrane contactor can diffuse the CO2 into the liquid.So the final product can control the degree of carbonation.The process of dissolving CO2 in the liquid is more controllable,and need less CO2 to achieve the degree of carbonation,at the same time, reduce the operation cost.

Degassing membrane (X50/X40 close gas membrane silk) technology is a new type of gas / liquid membrane separation process,By vacuum pumping, vacuum pumping+N2 method,the O2 removal rate is greater than 95%/99% in water,by method of blowing gas can make the CO2 removal rate is more than 95% in water,The users can also use series method to further improve the degassing effect.

“The design guides of CO2 and O2 removal by membrane method”please click into

Scope of application

-Remove the O2 in the liquid(< 1 ppb)

-Remove the CO2 in the liquid(< 1 ppb)

-Remove the N2 in the liquid

-Control humidity of gas

-Remove the micro-bubble in the liquid(Such as: photoresist, color ink, emulsion)

-The addition of hydrogen in liquid to control the dissolved hydrogen

-The addition of nitrogen in liquid to control the dissolved nitrogen

-The addition of carbon dioxide in liquid

Widely used in boiler feed water, food and beverage, semiconductor ultrapure water industry.

Degassing membrane compare with the traditional degassing tower

1. The traditional technology of removal of oxygen and carbon dioxide,bulky equipment, transportation and installation are not convenient , and the removal efficiency is limited, high operation cost.

2.Using the technology of KJ-Membrane degassing membrane, can be easily removed O2 to below 5ppb , the CO2 removal to below 1ppm, and the KJ-Membrane degassing membrane modular installation, the volume is reduced, the operation cost is cheap, the service life is over five years (water area), the automatic control, convenient use and maintenance.

The introduce of membrane contactor Leve 3 series process:

Membrane contactor Leve 3 series diagram

Use of degassing membrane:

(1)CO2 removal in liquid

The water for reverse osmosis (RO) and electric desalting (EDI) or continuous electric desalting (CDI) system must reduce the content of carbon dioxide (CO2) in water.High conductivity of electric desalting (EDI) or continuous electrical desalting (CDI) will decrease the resistivity values of yielding water.Dissolved CO2 in water is the main reason to cause the high conductivity .Kaijie Membrane Contactor degassing membrane provides a clean, free of maintenance and without any chemical added to adjust PH value,the method of removing CO2 in water ,the removal rate can reach 99.9%.If removing CO2, before EDI or CDI, then, will allow EDI or CDI produce higher quality of water,so that the water resistivity of original one level RO+EDI increased from 1 megabyte to 18 megabytes.After removing the dissolved CO2 in water,EDI/CDI on silicon and boron removal rate also increase,so that one level of RO + degassing membrane completely replace the previous two level series RO water,as the electric desalting (EDI) water become possible.

(2)O2 removal in liquid

Kaijie Membrane Contactor degassing membrane is widely used to remove oxygen in water and other liquid .Oxygen have a negative impact for many processes, it can corrode and oxidate material.In the field of electric power and other industrial, if not for degassing, pipe, boiler and the equipment will be easy to be corroded.Kaijie Membrane Contactor provides a method of deoxidization in water that without chemicals addition and large degassing tower,and it’s easy operation and modular.Also provides only need one step to achieve that removal both O2 and CO2, and the benefits of N2 control.Widely used in the field of semiconductor, in the field of semiconductor and film tablet industry, the high oxygen content can lead to low rate.In the field of microelectronics, Kaijie Membrane Contactor can meet index of dissolved oxygen< 1 PPB and provides the guarantee of performance.Fully provides a perfect solution to replace the degassing tower.

(3)Nitridation

Putting the nitrogen into the liquid, can improve some process.For example, if oxygen is removed in the liquid, and then some of the nitrogen is added to the water, and can improve the ultrasonic cleaning.KJ-membrance Membrane Contactor provides a perfect solution, because it is easy to remove oxygen ,and it can complete a controlled nitriding process.

In different engineerings of food & beverage industry put nitrogen into the liquid .If you want to have more bubbles or a thick layer of foam on top of the beer,nitridation is the best step .Membrane Contactor provides a simple and embedding step, can make the diffusion of nitrogen in a controlled process to add it, and produce a more stable products.

(4)Carbonation

Membrane Contactor provides a kind of simple and effective method of filling the carbon dioxide into the drink and liquid.Carbon dioxide gas is added to the beverage,can give the beverage foaming and stimulating.The addition of carbon dioxide can prevent deterioration, and reduce the bacterium of liquid.

Far better than spraying a large number of CO2 bubble to the liquid,membrane contactor can diffuse the CO2 into the liquid.So the final product can control the degree of carbonation.The process of dissolving CO2 in the liquid is more controllable,and need less CO2 to achieve the degree of carbonation,at the same time, reduce the operation cost.

Three-level series boiler feed water membrane contactor system |

90T/H Removing CO2 membrane system |

Pharmaceutical factory 15T/H membrane contactor system |

Medical industry to remove the O2 system |

33011002012349

33011002012349