Membrane filtration is a process by aperture size to separate, under the action of pressure difference on both sides of the membrane,membrane as the filter medium,and under a certain pressure,when the material liquid through the membrane surface, tiny pores on the surface of the membrane allow only water and small molecules to get through, as the permeate,and the material that volume is greater than the membrane pore size is trapped in the liquid side of the membrane,as the concentrated liquor,so achieve the purpose of separation and concentration.

[ Characteristics of concentration and separation UF membrane]

In the operation of normal temperature and low pressure, low energy consumption, so the equipment operation cost is low;

Equipment size is small, simple structure, low investment costs;

Simple process, easy operation and management;

Membrane filtration does not affect the molecular structure of the material liquid;

The wide application of concentration and separation UF membrane:

Suitable for biochemical and pharmaceutical product purification, separation, concentration, standardization, quality improvement etc.Such as:

★Enzymes and protein products ★Amino acids, peptides, antibiotics

★Flavonoids, pigment, etc. ★Biological fermentation agents

★Removing pyrogen ★Biological algae products

★Heparin sodium, chondroitin sulfate, biological polysaccharide ★Dairy product

★Oligosaccharides, monosaccharide ★Citric acid, malic acid and other organic acids

★Fruit and vegetable juice ★Brewing products (wine, vinegar, etc)

Note: The flux of concentration and separation UF membrane depends on the nature , moisture content and molecular weight cut-off of the material liquid,so users must through the experiment to determine the flux design.

[The performance parameters of concentration and separation UF membrane]

|

Model |

5050W-modified X50 |

9050W-modifiedX50 |

4040W-PS |

6040W-PS |

|||||

|

Performance |

Concentration design flux(0.15Mpa) |

180-400 L/h |

440-880L/h |

24-80 L/h |

70-250m3/h |

||||

|

Purification design flux(0.15Mpa) |

180~400 L/h |

440-880 L/h |

24-80 L/h |

70-250m3/h |

|||||

|

Specifications |

Type |

External pressure type |

External pressure type |

||||||

|

Membrane silks |

X50/80 elastic antipollution modified PP |

Hydrophlic PS |

|||||||

|

MWCO |

5-8(Ten thousand Dalton) |

0.3/0.5/0.6/1/2/3(Ten thousand Dalton) |

|||||||

|

Area |

38m2 |

90m2 |

8m2 |

25 m2 |

|||||

|

Silks quantity |

23000,1.2m/60000,1.2m |

7000,1m/21000,1米m |

|||||||

|

Max Pressure |

0.3Mpa |

0.30Mpa |

|||||||

|

Operation pressure |

0.15-0.20Mpa |

0.10-0.18Mpa |

|||||||

|

Residual chlorine concentration |

100ppm |

100ppm |

|||||||

|

Max temperature |

45℃ |

45℃ |

|||||||

|

PH |

0~14 |

1~14 |

|||||||

|

Operation mode |

Cross-flow filtration |

Cross-flow filtration |

|||||||

|

Process conditions |

Backwashing pressure |

0.15-0.25Mpa |

0.10-0.15Mpa |

||||||

|

Backwashing flux |

1.0-1.2T/h |

2.0-4.0T/h |

0.20-0.8T/h |

0.6-1.5T/h |

|||||

|

Chemical cleaning drugs |

HCL、NaOH、NaClO/NaOH |

HCL、NaOH、NaClO/NaOH |

|||||||

The above table design value as the experience value, if the user design, according to the data must be used by the lower limit value.

The performance, application, cases of concentration and separation UF membrane please click into.

The molecular weight of 100~5000 spiral UF membrane please click into

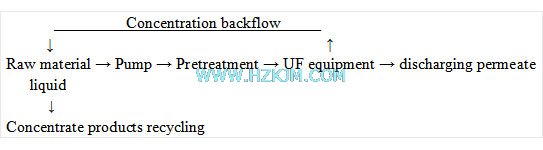

[The process diagram of concentration and separation UF system]

"The UF membrane"please click into

33011002012349

33011002012349