|

Model |

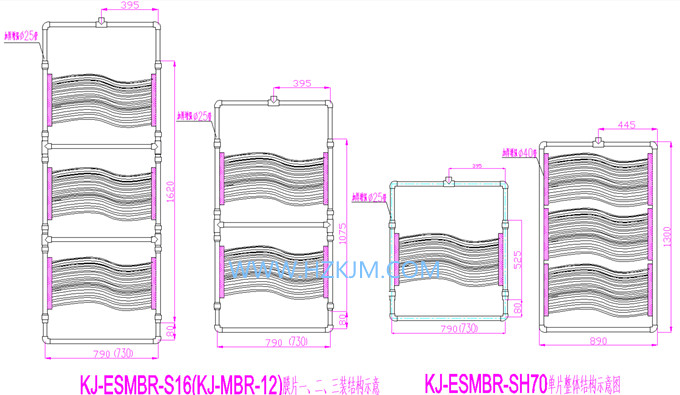

KJ-MBR-12 |

KJ-ESMBR-S16 |

KJ-ESMBR-SH70 |

|||||

|

Performance

|

Flux (M3/D) |

1.0 |

1.3 |

5.2~6.0 |

||||

|

Size(L*W) |

810X525mm |

1300X890mm |

||||||

|

Specifications |

Type |

Shade type |

With online cleaning type of shade type membrane |

|||||

|

Membrane area |

11.86m2 |

15.75m2 |

70m2 |

|||||

|

Material |

Modified PP |

X60 anti-pollution modified PP |

X60 anti-pollution modified PP/High porosity |

|||||

|

Max pressure |

-0.05 MPa |

|||||||

|

Max differential pressure |

0.05 MPa |

|||||||

|

Operating pressure |

-0.01~-0.05 MPa |

|||||||

|

Residual chlorine concentration |

2000ppm |

|||||||

|

Chemical cleaning |

yes |

Online cleaning,effect is better |

||||||

|

Max temperature |

45℃ |

|||||||

|

PH |

1~14 |

|||||||

|

Operating type |

Negative pressure suction |

|||||||

|

Process conditions |

Frequency of cleaning |

3~6 months |

||||||

|

Sterilization drug |

NaClO or Formaldehyde |

|||||||

|

Chemical |

HCL、NaOH、NaClO/NaOH |

|||||||

[The design size of membrane connection ]

[The installation diagram of MBR membrane frame]

Note: For the convenience of making membrane frame, can provide a molding standard MBR membrane slot (material: 6 mm thick PVC), please click into

[The installation design parameters of membrane bioreactor]

★ Frame material :Stainless steel square bar or A3 steel

★ Element spacing: 80~90mm

★ The distance between frame and biochemical pool wall ≥300mm

★ The distance between frame and frame ≥400mm(The best≥600mm)

★ Flux:ESMBR-S16≤200m3/d;ESMBR-SH70≤270m3/d

1.“The main pollution and anti-pollution method of MBR membrane”please click into

2、Download the MBR/ESMBR operation instruction please click into

[ Hydrophilic treatment and operation mode of the MBR membrane element ]

If the customers buy the hydrophobic MBR membrane element, for hydrophilic treatment before using, treatment method is using the 95% of the industrial alcohol to immerse about 15 minutes, and then rinse with water . If not use immediately after the hydrophilic, should be sealed packaging to keep membrane wet

六. Prevent to block the membrane hole and cleaning

Through the aeration system to produce bubbles and water flow, to make the membrane silks shake and clean. At the same time ,using the intermittent operation mode,

“Membrane bioreactor (MBR) and membrane element”please click into

33011002012349

33011002012349