The traditional

extraction methods of Stevia need flocculation, precipitation, decolorization

of activated carbon, adsorption of macroporous resin and ion exchange. It not

only increases the pressure of wastewater treatment, but also greatly reduces

the yield of stevioside. Stevia membrane extraction

can replace flocculation sedimentation, activated carbon decolorization, ion

exchange, etc., to achieve a significant reduction in the production of

wastewater, reduce energy consumption, but also to ensure the quality of Stevia

products.

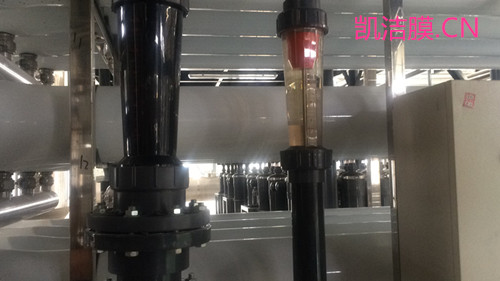

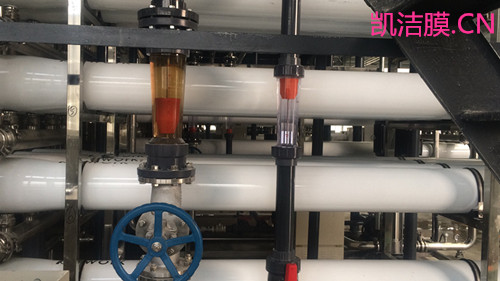

Kaijie membrane

company is related companies through a large number of experiments, in July,2017,successfully

implemented 1920t/d Stevia membrane separation and extraction system.

The system is

divided into 4 processes:

1. Sterilization and clarification membrane filter:

using 160 pcs Kaijie ultrafiltration membrane, the model is KJ-ESUF9050.

2. Decolorization and removal of protein membranes:

using 168 pcs of separation membranes , the model is 8040.

3. Concentration of waste liquid by membrane: using 156

pcs of concentrated separation membranes , the model is 8040. The concentrate is recovered as a semi-finished product, through the liquid as a reuse treatment.

4. Concentration of alcohol extracts: Using 208 pcs of

alcohol resistant concentrated separation membranes, the model is 8040. The concentrate is recovered as a semi-finished product, through the liquid as a reuse treatment.

The membrane separation system projects a total investment of over RMB 10 million yuan, and the following picture shows the project being in operation:

33011002012349

33011002012349